Industrial Safety Visit – Raghuleela Innovative Technology, Jakatwadi Satara

Acute Institute of Fire & Safety Satara branch students visited Raghulila Innovative Technology at Jakatwadi, Satara. We are thankful to Quality Incharge – Mrs. Madhuri Chougule, H. R – Rahul sir & Engineer – Vaibhav Mane for giving us such opportunity. Our students learned about below mentioned points during industrial safety training.

Purpose:

Our students visit this company to observe all the activities and the safety management followed by the company.

VISIT REPORT:

1) The company manufactured chocolates products.

2) There was 30% area reserve for environment there was planted so many trees for healthy ventilation and environment.

3) There was adequate access and egress.

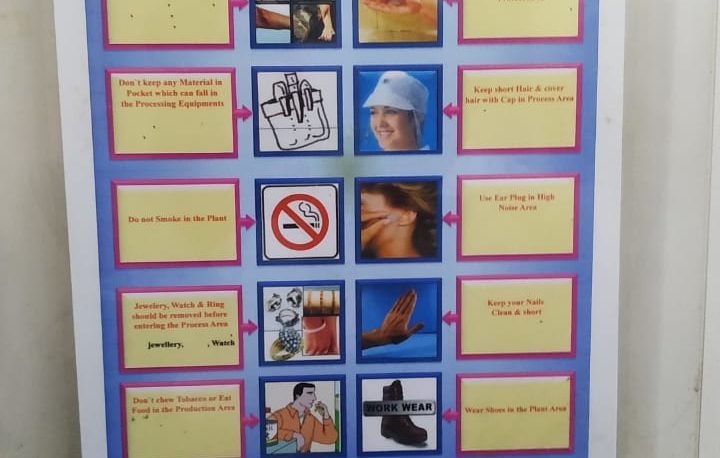

4) There was safety signs are placed at the necessary area.

5) The waste produced from the production in small quantity.

6) The company provide all the necessary facilities for employees .

7) There was adequate space for emergency exists.

8) Workers wear all the necessary personal protective equipment at work place.

9) Large storage area for storage all the products cool and dry at a place.

10) Company was followed all the food and environmental safety standards. Our students learn about how to do work safely at workplace.

Production department process:

1) Machine of ball mill first mix powder of chocolate …like milk powder ,coca butter, these powder mix minimum 7 hours then convert to liquid …then transfer to the storage tanks..

2) Minimum temperature of storage tank and calibration in one week ..and storage tank temperature check by every 2 hrs. them transfer to the molding tank.

3) In moldig depositor, deposit the chocolate by pipe line by tempering machine control by temperature.

4) Then deposit to mold for shape and sharpness and good quality for the chocolate.

5) Then transfer to the molding machine for 1 hr.

6) After one hour of the temper chocolate transfer to line by line in metal detector for checking of any metal in product and any small practical

7) Then transfer automatically to the packing

8) Packing by the first gold rap and then plastic rapper and pack to the box chocolate.

9) The product is ready for dispatch / sale.

10) Emergency stop alerts in machine in 8 point for product and workers safety.

Safety Observations:

1) In this chocolate factory there are available restroom for the employee.

2) Also available hand dryer for cold and hot water divided by separately, hand wash is also available.

3) Sign boards are present at entry and exit as well as necessary areas

4) Emergency roots are available for emergency conditions.

5) Proper Extinguishers (ABC) are available there

6) Good Housekeeping.

Are you looking better career options? Check our industrial safety courses & fire and safety courses.